Electrical Engineering

What is Electrical Engineering for Machine Safety?

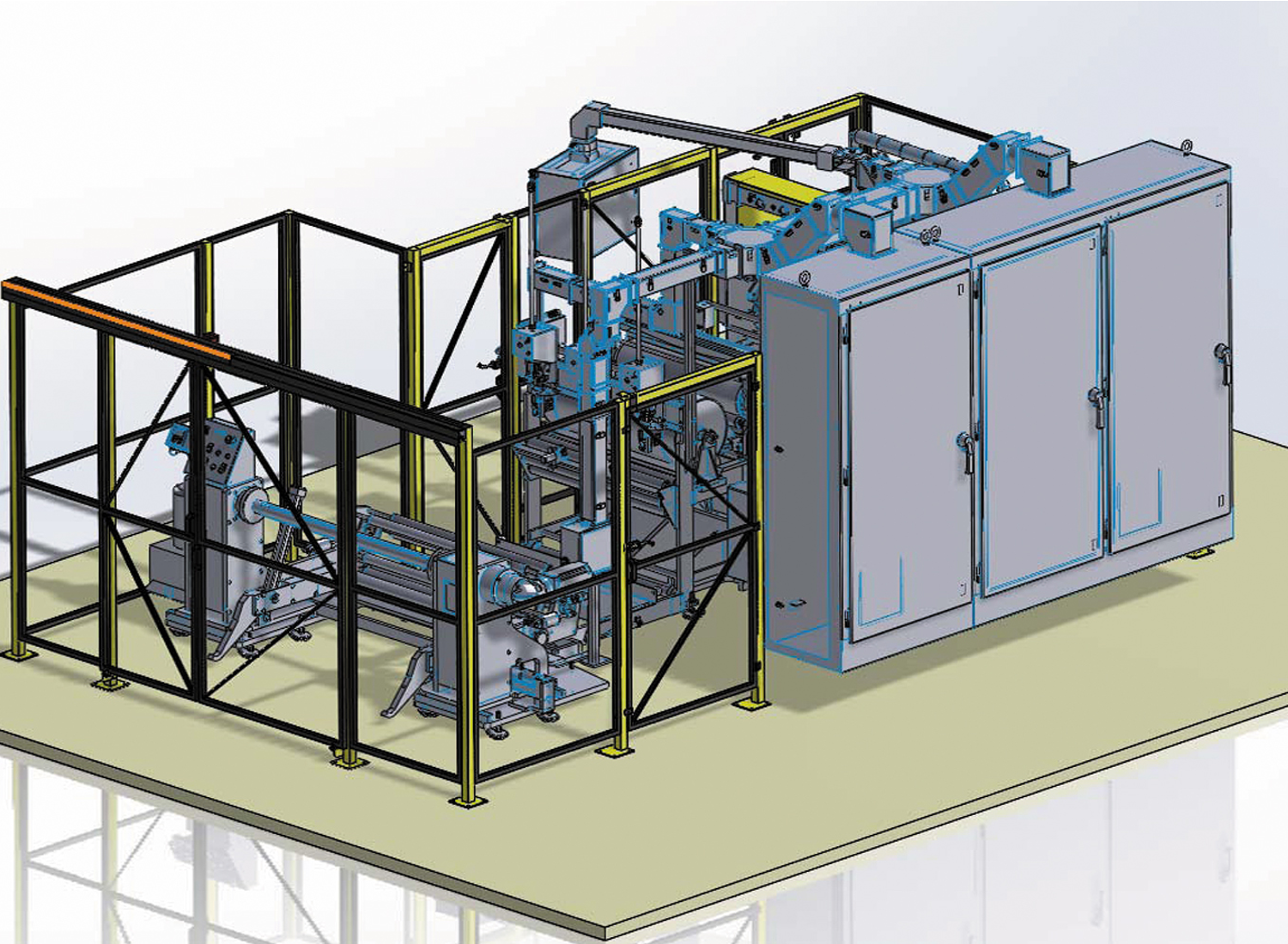

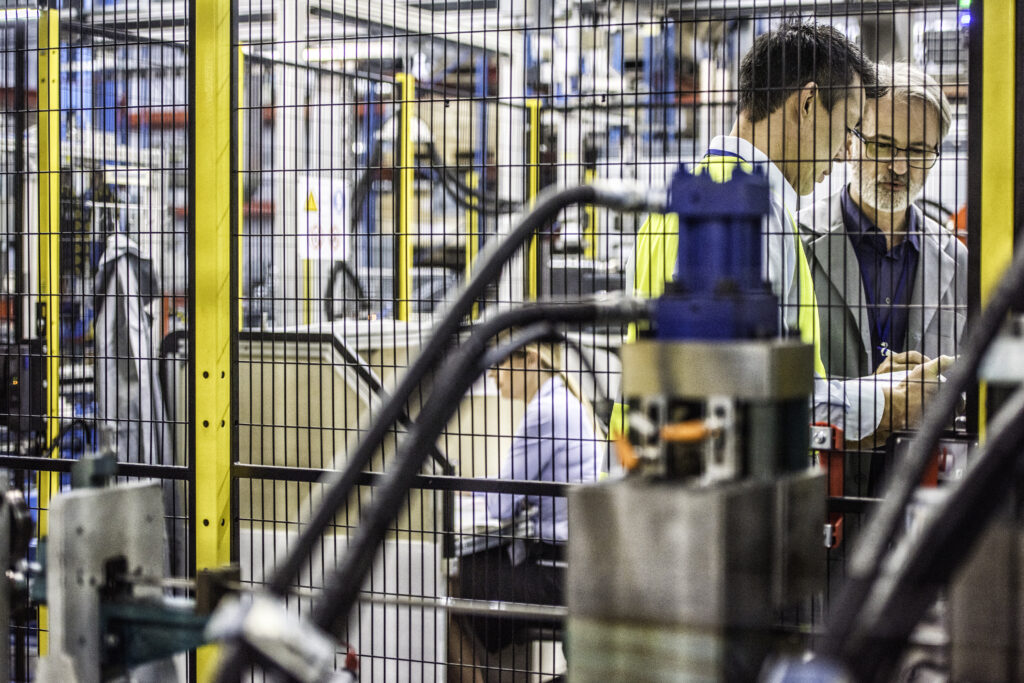

In modern manufacturing, warehousing and industrial operations, a machine’s electrical system is its central nervous system, dictating every movement, process and including safety-critical response functions. Effective electrical engineering for machine safety involves the expert design, installation, and verification of electrical systems to ensure they are robust, reliable, and compliant. This includes the careful design of safety circuits for specific manufacturing environments and machine guarding applications.

At Safety Systems Technology (SST), our services listed below ensure your machinery is not just compliant, but fundamentally robust, reliable, and productive.

The Strategic Value of Electrical Integrity

Investing in expert electrical engineering strengthens operational and overall business performance. A reliable, well-engineered electrical system enhances productivity by reducing costly downtime and building operator confidence. This strategic approach delivers tangible financial, operational and commercial advantages, from maximising machine uptime to strengthening your general reputation.

A Complete Range of Electrical Engineering Services

Safety Systems Technology offers a complete range of services to ensure your machinery’s electrical systems are designed, built, updated and maintained to the highest levels of safety and performance. Some of these services are related to specific standards.

- Control system design and integration (to BS EN ISO 13849-1): We design robust and fault-tolerant Safety-Related Parts of Control Systems (SRP/CS), engineering the optimal architecture to meet the required Performance Level (PLr) for every safety function.

- Electrical system design, build and commissioning (to BS EN 60204-1): SST offers an end-to-end electrical engineering service for your machinery, including control panel design, on-site installation and full commissioning to ensure flawless operation.

- Safety circuit design and implementation: Our team has extensive expertise in designing and implementing critical circuits, including fail-safe Emergency Stop systems, interlocking devices, two-hand controls and safety light curtains.

- Electrical system upgrades and modernisation: We conduct comprehensive audits of legacy machinery to identify compliance gaps and performance bottlenecks, upgrading outdated systems to meet current standards and improve reliability.

- Re-engineering of imported machinery: Importers of machinery from outside Great Britain are legally responsible for its compliance. When needed, we offer complete electrical redesign and rebuild services to guarantee equipment meets the requirements of the Supply of Machinery (Safety) Regulations 2008 and achieves PUWER compliance.

- Compliance audits, verification and testing: Our engineers provide independent testing and auditing to verify that your machine’s electrical equipment conforms to all relevant standards and its technical documentation.

- Technical documentation and UKCA/CE marking support: We assist clients in compiling complete and compliant technical files, including essential wiring diagrams, risk assessments and test results, to meet the requirements of the Supply of Machinery (Safety) Regulations 2008.

Request a callback

Core Safety Standards

The framework for modern machinery safety is built upon two complementary standards:

- BS EN 60204-1 provides the essential framework for electrical safety.

- BS EN ISO 13849-1 ensures the control systems that use that electrical equipment are reliable enough to perform their designated safety functions.

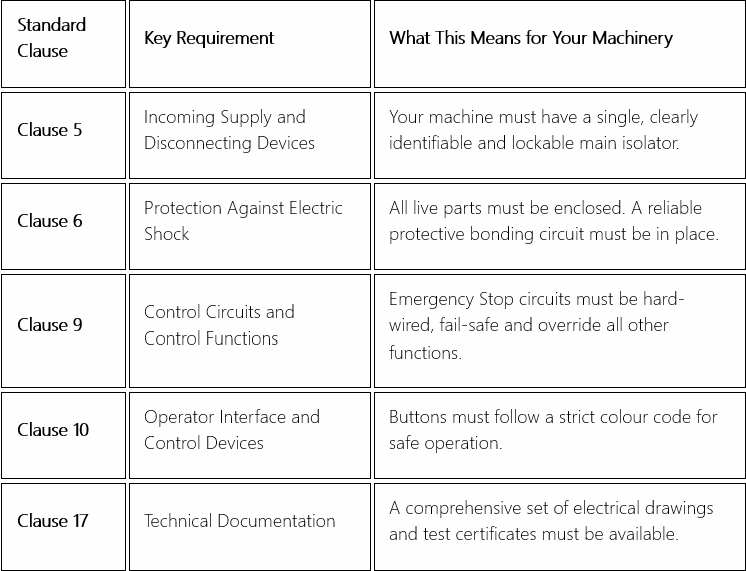

BS EN 60204-1: Fundamental Electrical Safety

This is the principal standard governing the electrical safety of machinery in the UK and throughout the EU. It applies to the entire electrical system of a machine from the point of supply, with the goal of promoting safety, ensuring consistent control responses and facilitating ease of maintenance.

| Standard Clause | Key Requirement | What This Means for Your Machinery |

|---|---|---|

| Clause 5 | Incoming Supply and Disconnecting Devices | Your machine must have a single, clearly identifiable and lockable main isolator. |

| Clause 6 | Protection Against Electric Shock | All live parts must be enclosed. A reliable protective bonding circuit must be in place. |

| Clause 9 | Control Circuits and Control Functions | Emergency Stop circuits must be hard-wired, fail-safe and override all other functions. |

| Clause 10 | Operator Interface and Control Devices | Buttons must follow a strict colour code for safe operation. |

| Clause 17 | Technical Documentation | A comprehensive set of electrical drawings and test certificates must be available. |

Ready to Enhance Your

Safety Systems?

From an initial survey and risk assessment through to meticulous installation and on-site commissioning to ongoing management assessment and preventative maintenance, our end-to-end service ensures effective, compliant, sustainable operational machinery guarding efficiency.

Get in touch with us today to ask for a no obligation survey

BS EN ISO 13849-1: Ensuring Functional Safety

At Safety Systems Technology, we have extensive experience of supplying machine guarding to facilities in very diverse range of industries. We’ve installed guarding for and continue to provide industry safety solutions to business from heavy industry to food tech, from polymer processing to pharmaceuticals, from logistics warehouses to scientific research laboratories. No machinery, environment internal or external phases us!

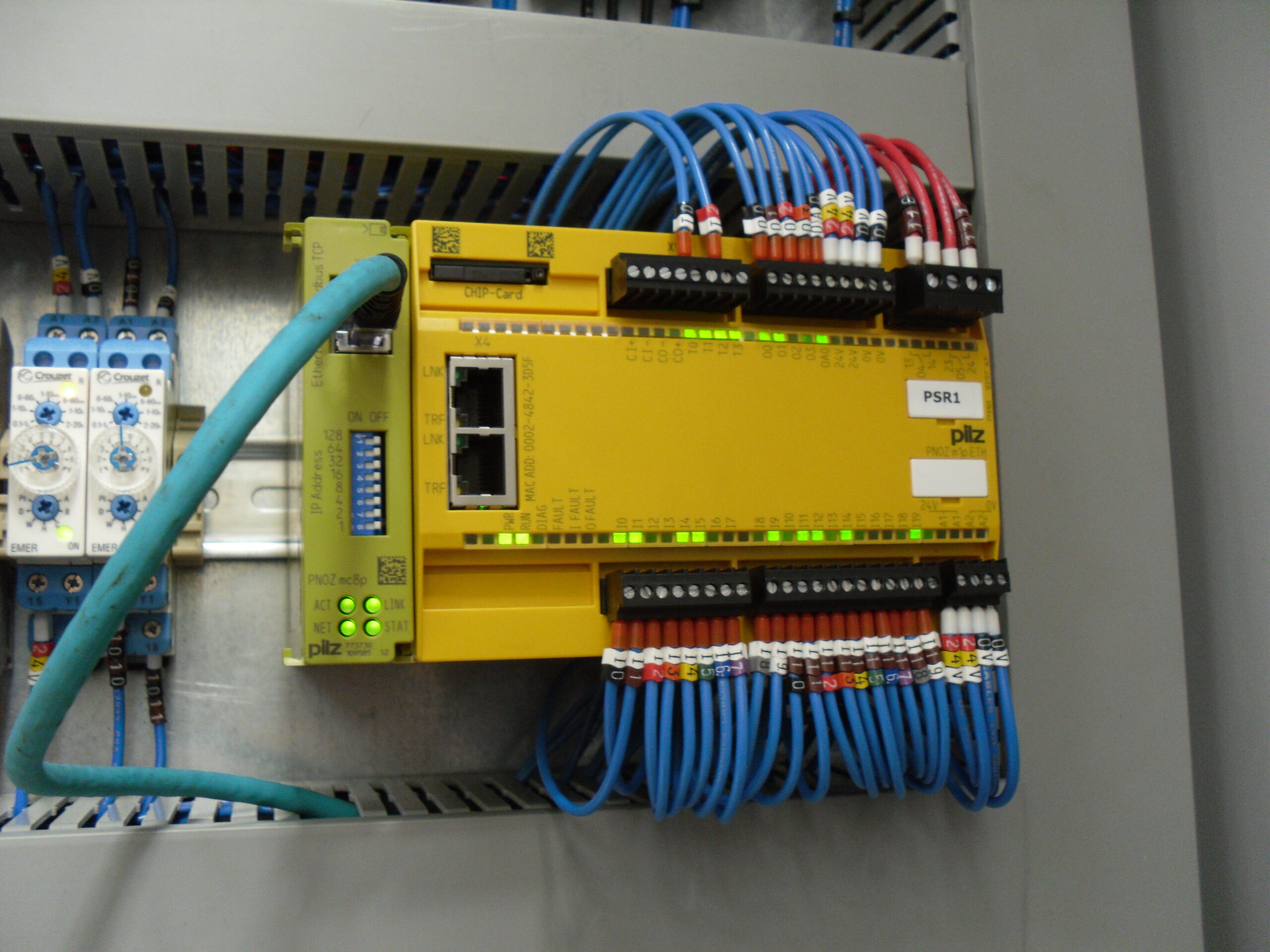

BS EN ISO 13849-1 focuses on functional safety. This is the part of a machine’s overall safety that depends on the correct functioning of its control systems. Rather than being a separate system, as is the case with older or legacy machines, modern machinery electrical safety is designed into the main control system. Often referred to as Safety-Related Parts of a Control System (SRP/CS), the functional safety system consists of:

Safety inputs

Safety inputs that detect hazards (e.g. safety light curtains, emergency stop buttons).

Safety logic

Safety logic that processes the signals (e.g. a safety programmable logic controller (PLC) or safety relays).

Safety outputs

Safety outputs that execute the safety command (e.g. contactors that de-energise a motor).

The goal of functional safety is to ensure that if a failure occurs, the machine will “fail-safe” – reverting to a safe state rather than a potentially dangerous one.

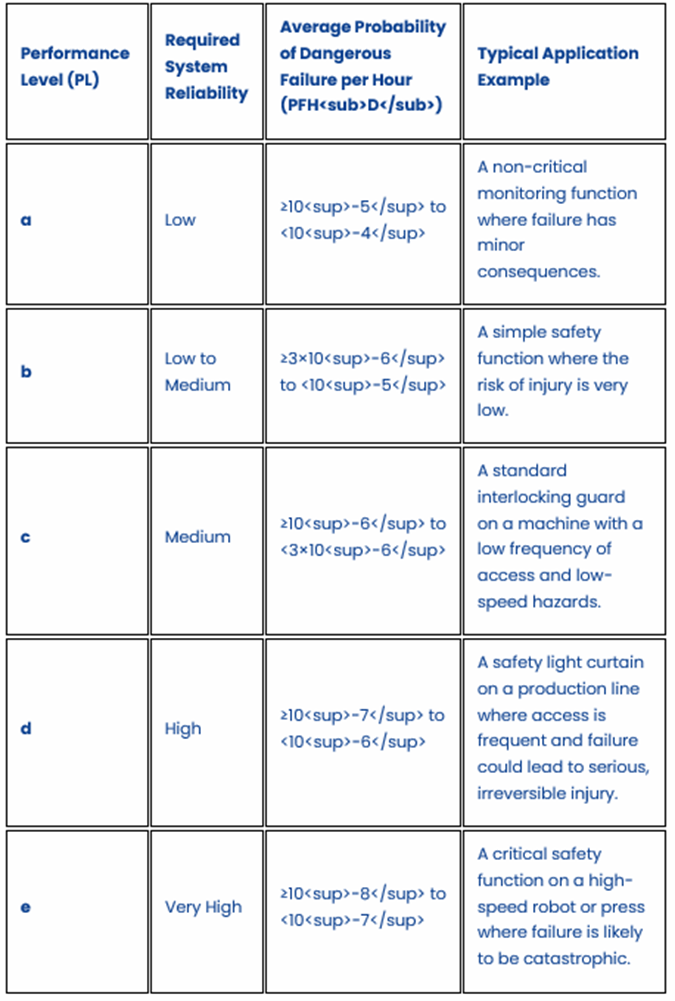

The purpose of the BS EN ISO 13849-1 standard is to answer the question: “How reliable is the control system that performs a safety function?” The core concept is based on a Performance Level (PL), a rating from ‘a’ (lowest reliability) to ‘e’ (highest reliability).

The required Performance Level (PLr) is determined through a structured risk assessment that considers three key factors:

S (Severity of injury)

From S1 (slight and reversible) to S2 (serious or fatal).

F (Frequency of exposure)

From F1 (seldom) to F2 (frequent or continuous).

P (Possibility of avoiding hazard)

From P1 (possible) to P2 (scarcely possible).

The combination of these factors determines the PLr that the safety control system must be designed to achieve. For example, a hazard that could cause a serious injury (S2), to which an operator is frequently exposed (F2), and which is scarcely possible to avoid (P2), would demand the highest required Performance Level, PLr = e. The safety circuit design must then achieve this target.

| Performance Level (PL) | Required System Reliability | Average Probability of Dangerous Failure per Hour (PFHD) | Typical Application Example |

|---|---|---|---|

| a | Low | ≥10-5 to <10-4 | A non-critical monitoring function where failure has minor consequences. |

| b | Low to Medium | ≥3×10-6 to <10-5 | A simple safety function where the risk of injury is very low. |

| c | Medium | ≥10-6 to <3×10-6 | A standard interlocking guard on a machine with a low frequency of access and low-speed hazards. |

| d | High | ≥10-7 to <10-6 | A safety light curtain on a production line where access is frequent and failure could lead to serious, irreversible injury. |

| e | Very High | ≥10-8 to <10-7 | A critical safety function on a high-speed robot or press where failure is likely to be catastrophic. |

Our Proven Five-Step Methodology

At Safety Systems Technology, we employ a structured process that provides transparency and minimises disruption, with a predictable and high-quality outcome, ensuring machine safety compliance with PUWER and optimising operating efficiency. The five steps are:- Assessment and risk analysis: We start with a thorough on-site assessment and risk analysis of your existing machinery and their electrical systems to identify any compliance gaps and potential failure points.

- Prioritisation and collaborative design: Based on this assessment, we work with your team to prioritise modifications and engineer a solution that is compliant, efficient, and aligned with your operational goals and how machinery is used.

- System integration and installation: Our team manages the complete installation process, from control panel building to on-site wiring, meticulously planning all work to minimise disruption to your production schedule.

- Rigorous testing and validation: Following installation, we conduct comprehensive functional and electrical tests to verify that the system performs exactly as specified and meets the stringent requirements of all relevant standards.

- Comprehensive documentation and handover: We deliver a complete and compliant technical file containing all schematics, risk assessments, calculations and certified test results, providing an essential record for future maintenance and audits.

Partner with SST for

Robust, Compliant and Productive Electrical Engineering for Your Machinery

Contact our expert engineering team today for a no-obligation consultation to discuss your electrical safety and compliance needs.

Our Services

Electrical Engineering

Enhancing safety with upgraded circuits and advanced electrical solutions.

Machine Guarding

Protecting workers with tailored perimeter and bespoke guarding systems.

Guarding Design

Creating innovative, user-friendly safety designs that provide optimal protection and efficiency.

Pedestrian and Vehicle Barriers

We supply and install a wide range of barriers in both steel or plastic, all of which are compliant with the relevant regulations More information

Compliance

Ensuring your operations fully meet PUWER, BS, EN and ISO safety standards for peace of mind.