Address: Unit 3, Westbury Street, Elland, HX5 9AT

Here at Safety Systems Technology, we fully recognise the numerous hazards involved with steel making. The industry involves risk-filled processes that must be carefully controlled with safety protocols. From molten metal handling and high-temperature furnaces to heavy-duty machinery and automated systems, prioritising safety is critical throughout all stages.

With our bespoke safety solutions, you can guarantee worker safety throughout steel making operations and meet PUWER, BS, EN and ISO regulatory standards.

There are many safety factors that must be controlled in the steel industry. When it comes to managing extreme heat and heavy machinery, plenty of operational hazards present them self, such as:

By addressing the various hazards presented in steel making, manufacturers can reduce workplace accidents and improve functionality, while adhering to strict industry standards.

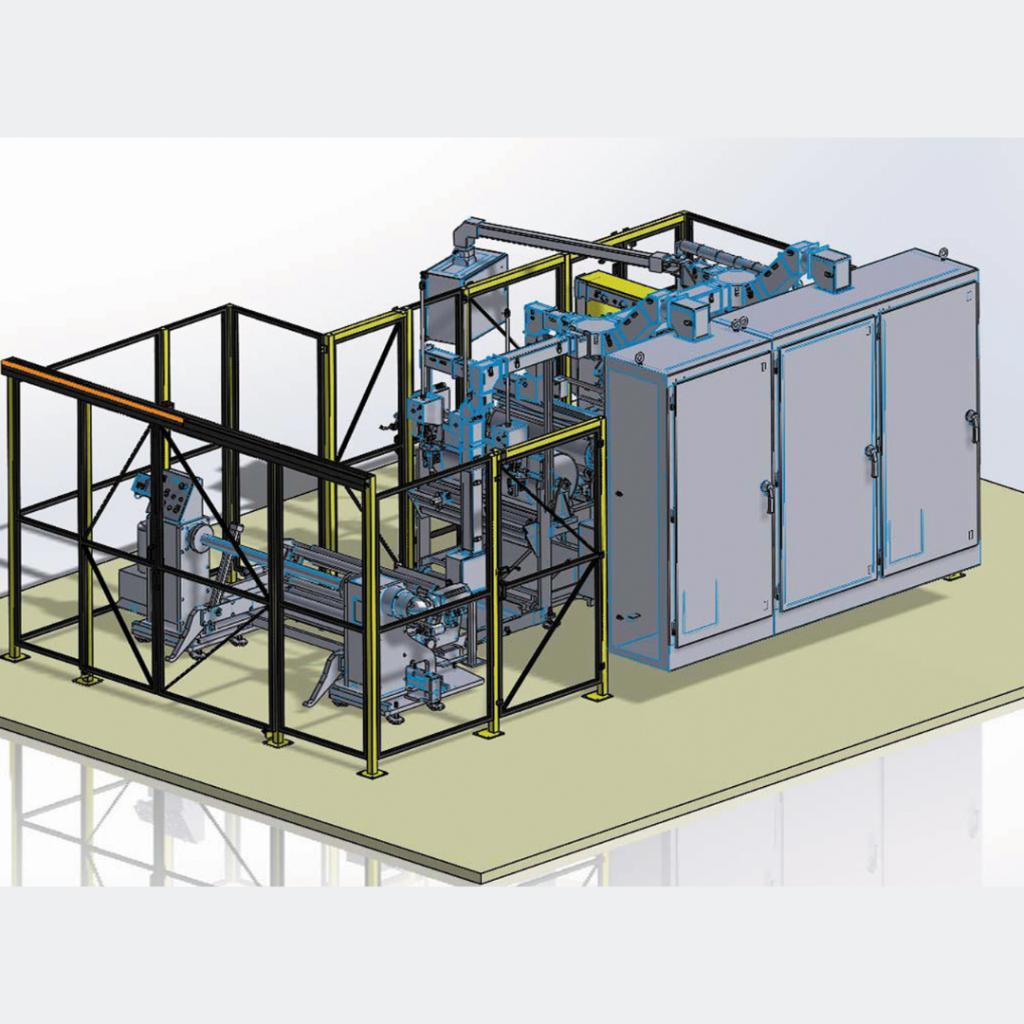

With our custom safety solutions, steel manufacturers will notice a significant shift in operational efficiency and workplace safety. For the steel making industry, we offer:

Our team of experts is here to help you achieve top-tier safety and compliance for your machinery and operations.

Whether you need electrical upgrades, custom guarding solutions, or PUWER assessments, we provide tailored services to meet your specific needs.

Get in touch with us today and take the first step toward safer, more efficient systems.

Enhancing safety with upgraded circuits and advanced electrical solutions.

Protecting workers with tailored perimeter and bespoke guarding systems.

Creating innovative, user-friendly safety designs that provide optimal protection and efficiency.

Ensuring your operations fully meet PUWER, BS, EN and ISO safety standards for peace of mind.