Guarding Design

Bespoke Guarding Design for a Safer, More Productive Workplace

We specialise in creating bespoke guarding designs that enhance safety and operational efficiency, ensuring full compliance with UK regulations. Effective machine guarding design is a systematic engineering process that goes beyond simply erecting a barrier. It involves a thorough understanding of the relevant duties and accountabilities under PUWER 1998, the application of detailed technical standards and a recognition of the operational realities and demands of your workplace.

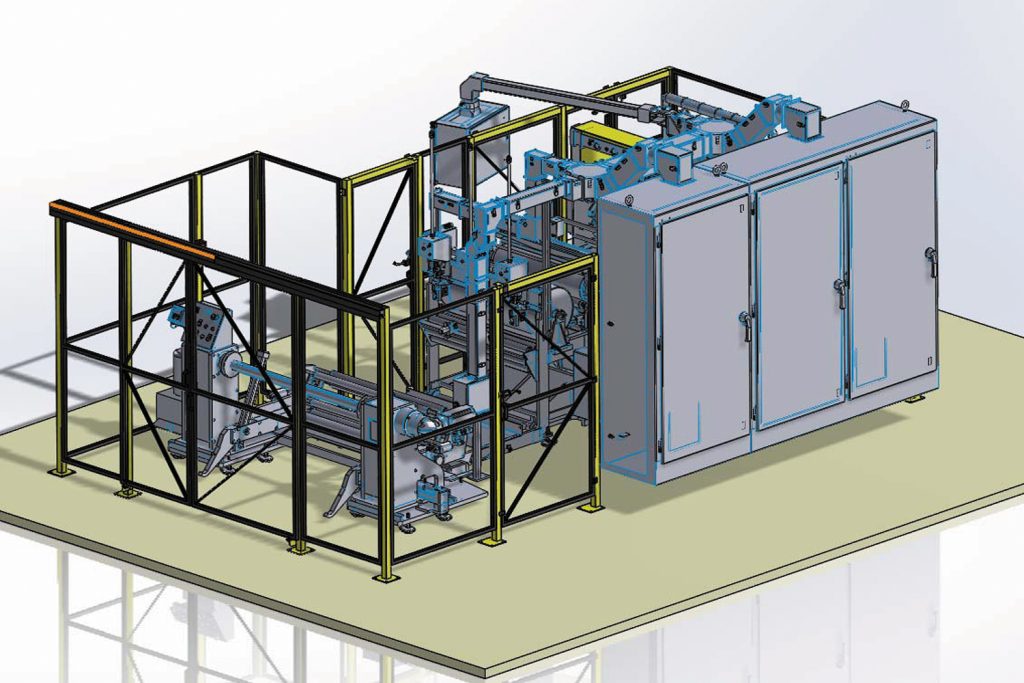

Our collaborative approach uses professional 3D modelling software to develop user-friendly solutions, designed to that integrate with your operations without disruption and protect your workforce.

Our Guarding Design Process

We follow a proven four-step process to develop tailored and compliant guarding solutions for your machinery.

- Consultation and risk assessment: We begin by carrying out a comprehensive risk assessment, to understand your machine and how it’s used in the context of its function and operational environment. This then is the foundation for a fully PUWER compliant design.

- Collaborative design and 3D visualisation: Using both measurements and photos of your machinery and its set up, we develop a detailed 3D CAD model using Autodesk Inventor. Providing customers with a visual indication of the proposed guarding solution at this stage facilitates review and gives a simple basis for feedback before fabrication begins.

- Fabrication and installation: We carry out fabrication of the guarding, typically composed of modular commercial off-the-shelf (COTS) systems, custom-fitted to your needs. Our experienced team then carries out the installation with minimal disruption to your manufacturing or warehousing operations.

- Validation and certification: Upon completion, we ensure the system is validated and provide all necessary documentation. Every guarding system we design and install complies with EN/UK standards and is CE/UKCA marked. We provide a Declaration of Conformity for full regulatory compliance.

Ensuring Full Compliance and Adherence to Standards

Our designs are developed to ensure you meet all your legal obligations under UK health and safety law, forming a key part of our Compliance services.

Provision and Use of Work Equipment Regulations 1998 (PUWER)

PUWER underpins UK workplace safeguarding legislation. The regulations make it clear that it’s the ongoing legal duty of owners to ensure machinery remains safe throughout its operational life, including installation, commissioning, routine maintenance and dismantling for disposal. Our designs strictly follow the hierarchy of controls mandated in PUWER Regulation 11, which prioritises fixed, enclosing guards wherever practicable.

PUWER Regulation 11 is not a menu of options but a strict, sequential hierarchy of control measures that must be followed. This hierarchy is fundamental to compliant guarding design in the UK.

Our design process is built around ensuring you meet these legal duties by applying the correct control measure in the correct order:

Fixed Guards

Fixed guards to enclose every dangerous part are the primary and preferred solution. They are logically the most effective guard since they are physical barriers that can only be removed with the use of tools.

Other guards and protection devices

Fixed guards are not always practical, for example because of the requirement for routine access, other measures are needed. These includes movable guards secured with interlocking devices or presence-sensing devices such as safety light curtains.

Protection appliances

If the measures referred to above cannot provide the requisite full protection, the regulations allow for the use of protection appliances such as jigs, holders, and push-sticks to keep the operator away from the danger zone.

Information, instruction, training, and supervision

This is a fundamental legal requirement that underpins the physical guarding. Without these essential procedures, the effectiveness of the entire safety system is compromised.

This hierarchical approach ensures our guarding designs are robust, effective, and legally compliant.

Bridging the UKCA Compliance Gap

A CE/UKCA mark indicates that a machine was safe when it left the factory. The ongoing legal duty under PUWER however, falls to the business that owns, installs, operates, maintains, or controls the equipment in the workplace to conduct a risk assessment of the machine as installed and used to address hazards created by its specific location, integration, or application. Our design process is specifically intended to bridge this compliance gap.

Harmonised Type-B Standards

We design in accordance with a suite of harmonised standards that provide the detailed technical specifications for compliant guarding. These include:

EN 14120 – Sets the general requirements for the design, construction, and durability of fixed and movable guards. It ensures the guard is robust enough to resist operational impacts and that its materials are suitable for the specific work environment.

EN 13857 – Defines critical safety distances by linking the size of any opening in a guard – whether mesh, or an aperture in a solid panel – to its required distance from a hazard. The relationship is two-way: a standard panel’s opening dictates the minimum distance, while a fixed space dictates the maximum permissible aperture.

EN 13854 – Specifies the minimum gaps needed to avoid creating new crushing hazards between the guard and the machine, or between moving and fixed parts. It ensures any gap is either too small for a body part to enter, or large enough for it to be present without being crushed, specifying values such as a 25mm minimum gap to protect fingers.

Machine-specific Type-C Standards

Where a specific Type-C standard exists for a machine – such as for industrial robots (EN 10218) or palletisers (EN 415-4) – its requirements take legal precedence over the general Type-B standards. We ensure our designs comply with any of the hundreds of Type-C standards which may be applicable to your equipment and its application.

From Panel Selection to Structural Integrity

An important consideration is the selection of guarding materials. The choice is often driven by the risk assessment and operational environment.

Panel Selection

Wire Mesh

This is the most common choice for perimeter guarding, combining visibility, ventilation and impact resistance. It is the standard solution for robotic cells and conveyor systems and forms the basis of many of our machine guarding installations.

Polycarbonate

Used when a solid, impenetrable barrier is required but operators nevertheless need a clear, unobstructed view of the process. It is ideal for containing liquids such as coolants or small particles.

Sheet Metal

Specified visibility is not necessary and maximum containment and impact resistance are key. It is the most appropriate solution for applications involving ejected materials such as liquids, hot swarf or sparks from welding. It can used either for the walls, or part of the walls of an enclosure. It is also often used for local guarding close to a machine’s moving parts to prevent fingertip injuries.

Structural Components

The framework supporting the panels is typically made from steel for high strength, or aluminium extruded profiles for a lighter, more easily modified system. For heavy industry applications – such as rail or steel fabrication – or where vehicles are present, we use heavy-duty posts and thicker gauge mesh or sheet metal to withstand significant impacts.

Specialist Finishes

For external applications or corrosive environments, we supply guarding with appropriate protective finishes. This is normally powder-coated galvanised steel. For hygiene-critical sectors such as food and beverage or pharmaceuticals, designs incorporate features such as round posts and fully welded joints to prevent contamination and allow for easy cleaning.

Designing for Access

Where personnel need to enter a hazardous area, the guarding must incorporate a safe, integrated access system.

Doors and Gates

We design and integrate various access solutions, including hinged, sliding and telescopic doors or gates to suit your machinery, its application and the available space. Functionally, a gate typically refers to an access point in a larger perimeter fence, while a door often describes a smaller panel on a machine enclosure.

Interlocked Guards

An interlocking device is required if a hazard does not stop immediately. This connects the guard to the machine’s controls, preventing the machine from starting while the guard is open and stopping it if the guard is opened during operation.

Safety Light Curtains

As an alternative to a physical door, safety light curtains can be used for access points that require frequent and rapid entry for tasks such as loading parts. However, they provide no protection from secondary hazards such as ejected parts or liquids, so they are only suitable where the risk assessment confirms that machine movement is the only significant hazard. Visit the Safety Light Curtain services page for more information on our services in this area.

Related Services

- Machine guarding: While this page focuses on the bespoke design process, our Machine Guarding service covers the physical supply and installation of standard and custom guarding solutions.

- Compliance: Our guarding designs are a key component of helping you achieve full compliance with PUWER and other UK machinery safety regulations.

- Electrical engineering: Our electrical engineers are experts in integrating interlocking devices, light curtains, and other safety components into your machine’s control system.

- Pedestrian and vehicle barriers: We extend the principles of safeguarding to the wider workplace by designing and installing robust barriers to segregate pedestrian walkways from vehicle traffic routes in warehouses and factories.

Why Choose Safety Systems Technology?

- Experience across multiple sectors: We have proven experience designing compliant guarding for diverse sectors, including aerospace and defence, heavy industry, food and beverage, pharmaceutical, manufacturing, warehousing and logistics.

- Standards-led design: Our entire process is rooted in a deep understanding of the PUWER regulations and the technical requirements of BS EN ISO standards.

- Collaborative 3D process: We work with you at every stage, using 3D CAD models to ensure the final solution meets your exact operational needs.

- End-to-end service: We provide a complete service, from the initial risk assessment and detailed design through to final installation and certification.

Discuss Your Guarding Design Project

Contact our specialist team to discuss your guarding design requirements. We will help you develop a solution that is safe, compliant, and efficient.

Request a callback

Discuss your guarding design requirements

Contact our specialist team for a no-obligation survey or to discuss your guarding design needs.