Compliance

Machinery Safety Compliance Services

At Safety Systems Technology, we partner with you to navigate the complexities of machinery safety compliance and legislation. Our expertise in machine guarding, electrical safety, PUWER and applicable standards, ensures your operations are not just compliant, but also efficient and productive.

We provide a complete, engineering-led service, from initial inspection and auditing to the design, implementation, and certification of robust safeguarding measures, giving you total peace of mind.

Understanding the UK Machine Safety Compliance Framework

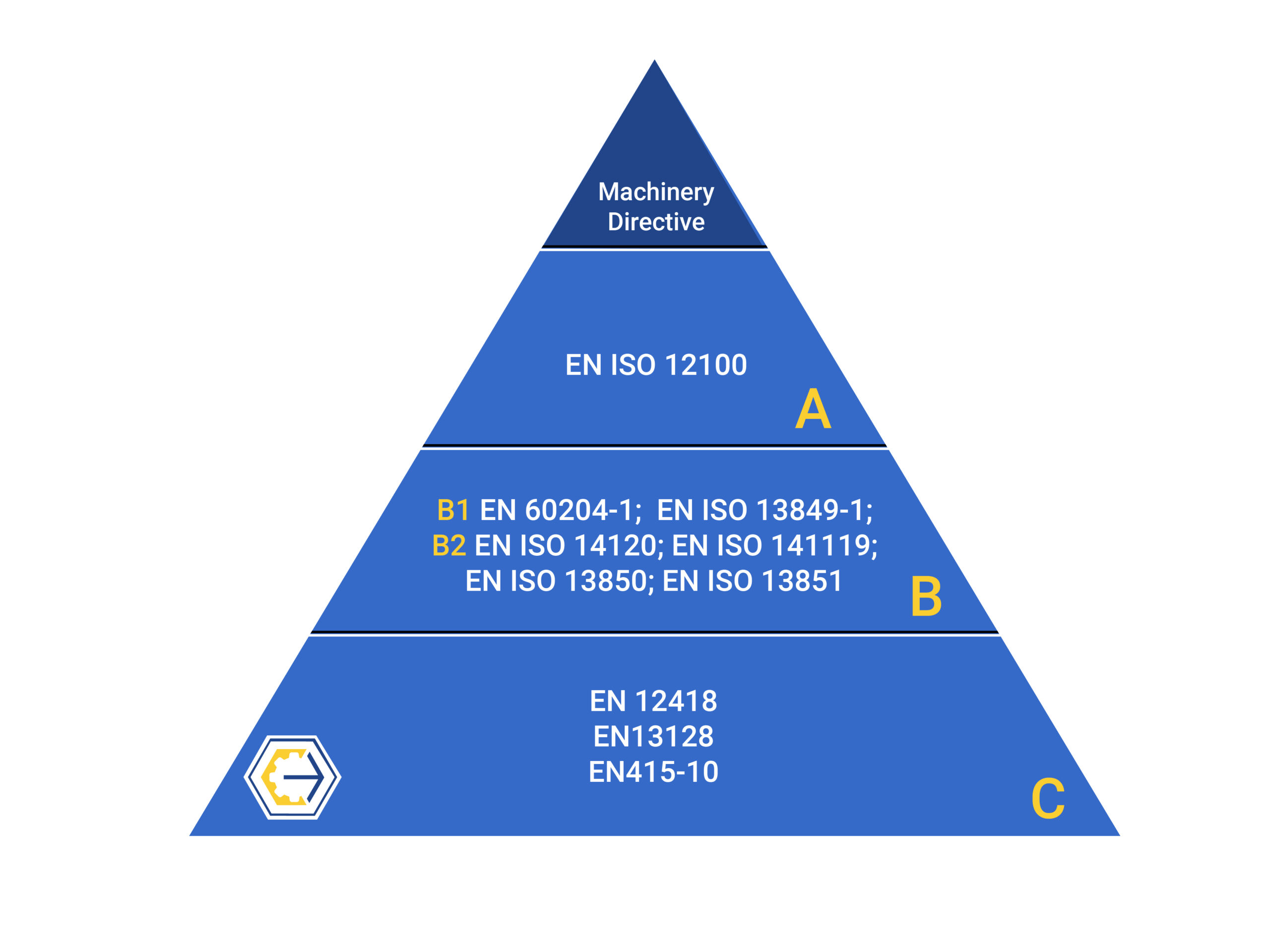

Navigating UK machinery safety law requires understanding a clear hierarchy of legislation and standards. As experts in the field, we guide you through every level to ensure comprehensive compliance. The framework is built on three tiers:

The Law

The Health and Safety at Work etc. Act 1974 establishes the fundamental legal duty for every employer to ensure the safety of their employees. This is the primary legislation under which all other regulations governing workplace health and safety sit.

Regulations

Specific duties are defined by legally binding regulations.

The Provision and Use of Work Equipment Regulations (PUWER) 1998 is critical, mandating that all machinery is safe, inspected, and maintained.

For those placing new equipment on the market, the Supply of Machinery (Safety) Regulations 2008 (or SMSR for short) applies however existing machinery undergoing major refurbishment or modification may also fall under the regulations.

Harmonised and Designated Standards

These provide the technical ‘how-to’. the standards needed to be implemented in order to comply with the the regulations. Adherence to them gives a “presumption of conformity” with the law. They are categorised to provide a clear structure:

Request a callback

Standard Categories

Type-A standards

Type-A standards cover basic risk assessment principles for all machinery.

Type-B standards

Type-B standards address specific safety aspects that apply across many machine types. They cover the general principles for design of guarding, interlocking and control systems.

Type-C standards

Type-C standards are highly specific, providing detailed requirements for a particular machine, such as a press or packaging machine. Where a Type-C standard exists, its requirements take precedence.

The diagram illustrates this hierarchy.

Furthermore, even if a machine is fully compliant with the SMSR, a business is expected to carry out a PUWER assessment when the machinery is installed since the regulations do not cover the installation and setup specific to how it will be used in given situation or location.

UKCA/CE Marking and when machinery owners are responsible

The primary responsibility lies with equipment manufacturers, who must ensure the machine meets all legal requirements before it is placed on the market. However, there are specific circumstances when the owners of machinery become responsible for the UKCA/CE) marking.

- Machinery built for own use: If you build a machine for use within your own company, you legally assume the manufacturer’s role and must complete the full UKCA/CE marking process.

- Significant Modification: If you substantially modify an existing machine, you are considered to have created a ‘new’ machine and must undertake a new conformity assessment.

- Importing for own use: If you buy a machine from outside Great Britain or the EU, and the machine is not UKCA/CE marked, you are legally responsible for its compliance with the Supply of Machinery (Safety) Regulations 2008.

Ready to Enhance Your

Safety Systems?

From an initial survey and risk assessment through to meticulous installation and on-site commissioning to ongoing management assessment and preventative maintenance, our end-to-end service ensures effective, compliant, sustainable operational machinery guarding efficiency.

Get in touch with us today to ask for a no obligation survey

Rely on us at Safety Systems Technology to Ensure Your Compliance

SST provides a comprehensive, end-to-end service designed to identify overcome any gaps in machine safety compliance. We ensure your operations are safe and legal and also efficient and productive. We take a structured, engineering-led approach, managing your entire machine guarding safety process from assessment and implementation through to certification.

Our services include:

- UKCA/CE Marking of Machinery: We are licensed to inspect and provide UKCA/CE marking.

- Functional Safety Validation (EN 13849 / EN 62061): Our engineers validate your safety-related control systems, determining the achieved Performance Level (PL) to ensure the reliability of functions like emergency stops and interlocks.

- ESPE/AOPD Stop-Time Testing: For equipment using light curtains (ESPE) or laser scanners (AOPD), we conduct precise on-site stop-time measurements to verify that safeguards are positioned at a safe distance in line with EN ISO 13855.

- Electrical Safety Testing (EN 60204-1): We conduct rigorous testing of machinery’s electrical systems to verify the safety of control panels and installations.

- Workplace Traffic Management: We design and install pedestrian and vehicle barrier systems compliant with BSI PAS 13:2017 and HSE INDG199 guidance, ensuring clear segregation and protection in busy operational areas.

Want to find out more?

To ensure your machinery guarding and electrical systems are fully compliant and optimised for performance, contact our expert engineering team today for a no-obligation survey and PUWER risk assessment.